|

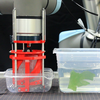

Manipulation of Aquatic Organisms

We will promote research on manipulation of aquatic organisms. We attempt to grasp and manipulate swimming organisms (nekton), drifting organisms (plankton), and benthic organisms (benthos) by utilizing physical interactions with the environment.

|

|

|

Inflatable Robots

We will promote research on inflatable robots, which consists of bendable membranes inflated by air pressure.

|

|

|

Food Samples

We will fabricate food samples reproducing the deformation and friction properties, which affect food handling, to apply the samples into food handling experiments.

|

|

|

inductancesensor

We will develop proximity sensors based on magnetic permeability measurements.

|

|

|

Fabric Manipulation

We will develop robotic hands for grasping and manipulating fabrics. The goal of this research is to separate piece of fabric from a stack one by one, grasp and place a separated fabric.

|

|

|

Bellows Actuators

We will establish physical model of bellows actuators and design bellows actuators realizing various deformations.

|

|

|

Fabric Interface

We will develop a fabric touch panel using to drive a stuffed animal robot.

|

|

|

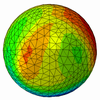

Probabilistic Modeling of Food Shapes

A probabilistic method for modeling food shapes with variation will be established. Each food item has its large variation in its shapes and sizes, which affect food grasping and manipulation. We apply probabilistic modeling to food shapes.

|

|

|

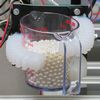

Physical Twin of Living Organisms

We build physical twins of living organisms mimicking their behavior for manipulation. Physical models of living organisms will be applied to experiments in grasping and manipulation of living organisms.

|

|

|

IPMC Sensors in Soft Hands

We apply IPMC sensors developed by AIST to soft hands to estimate physical quantities of grasped objects.

|

|

|

Wrapping Gripper

We propose a wrapping gripper to grasp chopped or granular food materials. A wrapping gripper consists of multiple inflatable soft fingers. Fingers will expand according to air pressure so that the gap between neighboring fingers shrinks, with successfully grasping chopped or granular food materials.

|

|

|

Thin Planar Shell Gripper

A thin planar shell gripper is proposed to pick and place food materials in a narrow space. We develop novel structure and fabrication method of thin fingers that can be inserted into a narrow space.

|

|

|

Shell Gripper

We propose a shell gripper to grasp soft but heavy food materials. A shell gripper consists of a rigid outer shell, with soft pneumatic chambers inside. By applying air pressure, soft chambers will expand, enabling to grasp a food material inside the shell.

|

|

|

Scooping-Binding Hand

A scooping-binding hand is proposed to grasp slippery and fragile food materials. This hand is capable of grasping food materials by scooping the materials by thin elastic plates attached to the fingers and binding them by parallel elastic threads.

|

|

|

|

|

|

Conductive Fabric Sensor

We will study proxomity sensing using conductive fabric. We will develop a fabric sensor that can be wrapped around an inflatable arm and establish a sensing algorithm robust against parasitic capacitance.

|

|

|

Mechanics of Jumping

We will investigate the deformed shape of a circular spring mechanism that mzximizes its jumping height. We will design a mechanis that realizes the obtained deformed shape, with analyzing the mechanics during jumping to find out the principle for heigher jumping.

|

|

|

Needle Gripper

This research proposes a pneumatically driven needle gripper that can penetrate confined areas and grip shredded food materials. This needle gripper has an air chamber on which needles are attached. Controlling air pressure inside the chamber will realize two action: penetrating and gripping.

|

|

|

|

Micro Pneumatic Valve

We develop a micro pneumatic proportional valve that can be embedded into pneumatic muscles and can control air flow of 0.5 MPa pressure and 5 l/min flow rate to drive the pneumatic muscles.

|

|

|

Jamming Hand

We will perform fragile object handling using jamming hands.

|

|

|

|

|

|

|

|

|

Bend Sensing of Soft Fingers

We will fabricate soft fingers embedded with polymer sensors to measure finger bending. We will detect finger bending vibration and slippage during grasping based on sensor signals.

|

|

|

Separate Drive Gripper

This research proposes separate drive grippers, where grasping parts and driving parts are remotely located. We apply the proposed separate drive grippers to living creature handling.

|

|

|

Mechanical Modeling of Breasts

We will build a biomechanical model of breasts. We build finite element models of breasts to compute their deformation against external loads.

|

|

|

Food Handling Database

This research aims at constructing a database between food materials and robotic grippers to clarify how deformation and surface properties of food materials affect the grasping of food materials by robotic grippers.

|

|

|

Food Property Sensing

This research aims at non-destructive measurement of food physical properties. Providing vibration to a food material, we measure its viscoelastic nature.

|

|

|

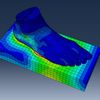

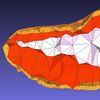

Mechanical Modeling of Foot

The aim of this research is mechanical modeling of flatfoolt. Based on images of foot, we build a finite element model of flatfoot and perform physical simulation of walking and surgery.

|

|

|

Vision for Food Handling

We will propose a method to estimate the grasping location based on depth images in order to a certain amount of granular food materials. We apply machine learning to pre-obtained depth images and picking amount data to determine an appropriate grasping location.

|

|

-100x100.png)

|

Prestretched Hand

We will propose a prestretched hand consisting of curved soft fingers at their natural state in order to pick up thin food materials. Gluing a film on the innee side of a extended printable finger yields a prestretched finger.

|

|

|

Capacitive Force Sensor

We will study a soft capacitive sensor capable of sensing a desired physical quantity. Designing structure or material of dielectric, we will realize a sensor that can measure force alone independent of contacting area.

|

|

|

Printable Hand

We will apply a 3D printer that can print soft materials to fabricate soft robotic hands with their application to soft object handling.

|

|

|

Binding Hand

We propose a novel robotic hand based on the concept of binding to grasp and handle soft food materials. Binding applies elastic threads instead of rigid fingers for grasping. Binding hands are capable of picking up deformable cups with food materials and packing them in to a lunch box.

|

|

|

Soft Fingertip Sensor

We will fabricate a force sensor embedded with a soft fingertip. The sensor consists of Hall-effect devices and permenent magnets.

|

|

|

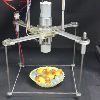

Contacting Operations by Aerial Robots

The aim of this research is to develop aerial robot systems to perform physically interacting operations with the environment. We introduce end-effectors to aerial robots to perform a wide range of operations such as branch cutting in forestry, window cleaning of buildings, and hammering test of constructions.

|

|

|

Aerial Pruning

This research aims at pruning tree branches using an aerial robot. We propose a skew-gripper for fixing an aerial robot to a branch and pruning a branch by a cutting tool.

|

|

|

Food Handling

This research aims at automatic handling of food objects by robotic systems. Food object handling requires less accuracy but capability to cope with variance in shapes and locations of food objects. Based on caging, we will design a robot hand that can cope with such uncertainties to perform automatic handling of food objects.

|

|

|

Food Modeling

This research will establish a modeling method of food to simulate food manufacturing and food eating processes. We will build a simulation model of manufacturing process of Japanese sweets.

|

|

|

Soft-fingered Manipulation

The goal of this research is to perform dexterous and stable object manipulation using soft-fingered mechanical hands. The location of a manipulated object measured by a realtime vision system and the grasping force measured by a tactile sensor are fedback to the hand motion to realize stable grasping and manipulation. We are interested in the modeling of soft fingertips and the control law for grasping and manipulation.

|

|

|

Surface Bend Sensor

This research aims at sensing of surface deformation. We will apply multiple conductive patterns to estimate the deformation of a bendable plate.

|

|

|

Fiber Sensor

This research focuses on deformation sensing using electro-conductive yarns.

|

|

|

Mechanical Modeling of Fingers

We will build a biomechanical model of vitreous humor. Based on force and displacement measurements through a micro robot moving inside the vitreous, we will estimate deformation properties of the vitreous to build up its finite element model.

|

|

|

Slip Sensing Sensor

This project focuses on slip detecting sensors. Using a fabric sensor consisting of conductive yarns and a set of accelerometers embedded in a soft fingertip, we will perform incipient slip detection and texture recognition.

|

|

|

Crawling and Jumping Soft Robots

In this research, we will develop a robot capable of rough terrain locomotion by its rolling and jumping. A robot consisting of deformable soft body and flexible actuators can roll and jump on a ground by the deformation of its deformable body.

|

|

|

Tensegrity Robots

In this research, we will investigate a robot that moves over terrain via the deformation of tensegrity structure. The body consists of rigid elements connected by tensional members. Deformation of tensegrity structure yields the locomotion over terrain.

|

|

|

Underwater Vision

We develop a vision system capable of finding and tracking a target under the water. In Lake Biwa, where optical nature is different from the air and there exhibits many floating micro objects, we will develop a system to find and track fish in the lake.

|

|

|

Belt Object Manipulation

The goal of this research is to realize the manipulation of belt objects such as flat cables and flexible circuit boards. Deformation properties are estimated through visual observation of object deformation to determine the trajectory of a manipulator handling the object.

|

|

|

Mechanical Modeling of Eyes

Here we will build a biomechanical model of vitreous humor. Based on force and displacement measurements through a micro robot moving inside the vitreous, we will estimate deformation properties of the vitreous to build up its finite element model.

|

|

|

Mechanical Modeling of Liver

This research will establish a method to build the deformation model of non-uniform biological objects based on their inner measurement. We will obtain the deformation field inside the object using CT and MRI to estimate non-uniform deformation parameters.

|

|

|

Micro Parts Feeding

The goal of this project is to realize vibration drive of micro electric parts such as chip condensers and resisters. We apply asymmetric surface (saw-tooth surface) with symmetric vibration (sinusoidal vibration) to realize one-directional motion of micro parts. We are analyzing dynamics of micro parts during feeding.

|

|

|

Manipulation of Deformable Linear Objects

In this research, we will explore the manipulation of deformable linear objects such as cables, cords, and tubes. Based on linear object modeling, we will establish control strategy to perform the manipulation of linear objects.

|

|

|

Belt Object Modeling

The goal of this research is to establish the modeling method for deformable belt objects such as flat cables and flexible circuit boards. A modeling method, which is based on differential geometry, is developed to describe bend and twist of a belt object.

|

|

|

Needle Insertion Simulation

This research aims at dynamic simulation of needle insertion process in medical surgery. We will establish a method to simulate the needle insertion process without remeshing and a method to estimate physical parameters in the insertion.

|

|

|

CMOS+FPGA Vision

We develop a CMOS+FPGA vision system to perform fast (1,000fps) and high-resolution (1,000x1,000 pixels) visual feedback. A CMOS image sensor realizes fast capturing of successive images and an FPGA where vision algorithms are implemented enables realtime computation of features for visual feedback.

|

|

|

Soft Interface

The goal of this research is to control mechanisms including soft interface. Through the simultaneous control of motion and deformation of a soft object and the control of a loosely coupled joint, we reveal the interaction between mechanics and control in the control of mechanisms with soft interface.

|

|

|

Cloth Expansion

This project aims at the development of a mechanical system that performs unfolding of clothes. The unfolding consists of grasping, expansion, and placing operatoins. We analyze dynamic expansion by pinching slip motion.

|

|

|

Virtual Rheological Objects

We will construct virtual rheological objects in VR space and will realize haptic sensation at the contact with rheological objects. Research topics include reality-based modeling of rheological objects, volmatic visualization of deformation inside rheological objects from CT and ultrasonic images, and haptic rendering of rheological deformation.

|

|

|

Linear Object Modeling

The goal of this project is to establish the modeling method for deformable linear objects such as cords and tubes. Differential geometry method is developed so that bend, twist, and extension of a deformable linear object in 3D space can be described on a computer.

|

|

|

FPGA-based Realtime Vision

We will develop realtime vision chips attachable to a robotic hand. Vision algorithms to detect the position and the orientation of a planar motion object are implemented on FPGA's to perform them within the video-frame rate.

|

|

|

3D Imaging

In this project, we will develop a 3D imaging system using a varifocus mirror. Multiple images with various focus distances can be obtained by use of the varifocus mirror. Applying Shape-from-Focus technique, we can compute an entirely-focused image or a 3D distance image.

|

|

|

Deformable Pneumatic Actuators

We will develop deformable pneumatic actuators. Embedding linear constraints on an elastic rubber tube yields a single-motion actuator (SMA). We will then construct a pneumatic group actuator (PGA) composed of multiple SMA's.

|

|

|

Cloth Positioning

The goal of this project is to derive operation strategy and control law for the positioning of multiple points on an extensible cloth. Distributed manipulation system is developed for this positioning and a novel control law for the positioning is derived based on a coarse model of a cloth.

|

|

|

Card Separation

In this project, we will develop a mechanical system that separate stacked cards and control the location of separated cards.

|

|

|

|

|

Rheological Object Forming

The goal of this project is to perform the automatic forming operations of rheological objects such as dough, paste, and jerry. Novel forming machine and forming control law using vision sensing are developed for the automatic forming of rheological objects.

|

|

|

Vision-based Object Picking

We will develop a mechanical system that can grasp and manipulate a fast planar-motion object on a table. Grasping and manipulation of an object are preformed by feeding back the position and the orientation of an object to a 7-axis manipulator PA-10.

|

|

|

Extraction of Human Manipulative Skills

The goal of this project is to establish a technique to extract human skills in manipulation and to transplant these skills in a mechanical manipulator. We have applied our method to the insertion of a deformable tube into a plug.

|

|

|

Modeling of Human Upper Limbs

The goal of this project is to construct a computer model of human upper limbs and to analyze human manipulative operations using the developed model.

|

|

|

Design and Learning of Force Control Laws

The goal of this project to establish a method to determine admittance control parameters appropriate to individual mating operations. We will develop an analytical method to design admittance matrices and commanded motion in mating operations based on the modifiability of the operations.

|

|

|

Impulsive Sorter

The goal of this project is to develop a impulsive sorter, which enables fast object sorting with high flexibility. Air floating and sorting using collision enable fast sorting and vision-guided sorting provides high flexibility.

|

|

|